Building a house from plastic waste

Researchers are developing 3D-printed floor beams made from plastic waste that meet building regulations and could replace wood in housing construction in the future. The approach is aimed at lightweight, modular constructions and making plastic waste usable as a resource in global housing construction.

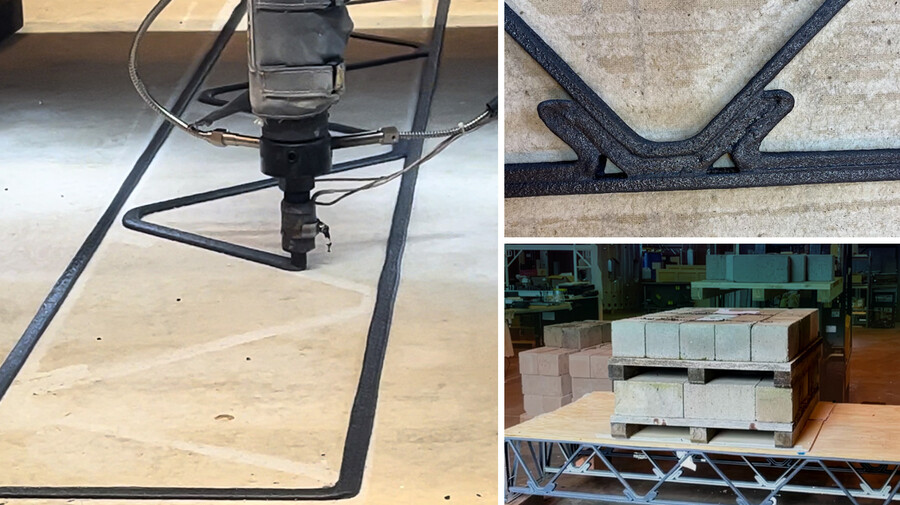

Photo: Courtesy of the researchers / MIT

Today’s PET bottle could be part of a floor beam tomorrow, as a load-bearing element. A research team at the Massachusetts Institute of Technology is investigating how recycled plastic can be shaped into load-bearing components using large-format 3D printing. The focus is on a beam system that has been specially developed and tested for use in residential construction.

Plastic trusses instead of wood

The new beams look familiar at first glance, as they are based on the geometry of classic wooden trusses. A frame with diagonal struts absorbs and distributes forces, a construction method that has been tried and tested for decades. What is new is the material and production. A composite of recycled PET and glass fibres is used for printing, which provides rigidity and stabilizes the pressure behaviour. Each beam measures around 2.4 m long, around 30 cm high and a good 2.5 cm wide, weighing only around 6 kg and therefore significantly less than a comparable wooden beam. The production time is short, less than 13 minutes per component is sufficient for printing.

Load test under practical conditions

In order to test its suitability for everyday use, the team assembled four beams in parallel and screwed them together with a wood-based panel to form a floor frame measuring approximately 1.2 by 2.4 m, a common grid dimension in the USA. The surface was then gradually loaded with sandbags and concrete weights, while the deflection was continuously measured. Up to a load of around 140 kg, the deformation remained well below the limits permitted by US building regulations. Only when the total load exceeded 1,800 kg did the construction fail, the beams buckled and broke. This indicates that the rigidity is generally sufficient to meet the relevant requirements in residential construction.

Lightweight, modular, quick to assemble

In addition to the load-bearing capacity, the low weight is a key advantage of the system. The plastic beams can be transported using a pickup truck, which simplifies logistics and handling on the construction site. Assembly follows the principle of classic timber frames. The elements are screwed together on site and joined to form a load-bearing skeleton. In the long term, the concept is aimed at modular house frames in which the floor, walls and roof consist of standardized, printed components. This approach is particularly interesting for regions where wood is scarce or expensive.

Plastic waste as a raw material for a billion houses

The project was triggered by the enormous global demand for housing. AJ Perez from the MIT School of Engineering points out that around one billion new houses will be needed by 2050. A demand that can hardly be met with wood alone without clearing gigantic areas of forest. Instead, existing waste streams should be used. Disposable plastics such as bottles or food packaging will be given a second life as a construction product. The aim is to create components that are lighter, more durable and more sustainable than conventional alternatives.

Costs, standards, long-term behavior

Despite the promising results, the technology is still in its infancy. The actual costs on an industrial scale, the adaptation of standards and approval processes and the long-term behavior of the components under weathering, UV radiation and changing loads are still unclear. Nevertheless, the project opens up exciting prospects for planning, development and the construction industry. 3D-printed supporting structures made from recycled plastic could change the material mix in building construction. Provided that cost-effectiveness and durability can be convincingly demonstrated.