Electrochemical breakthrough in the fight against contaminated sites

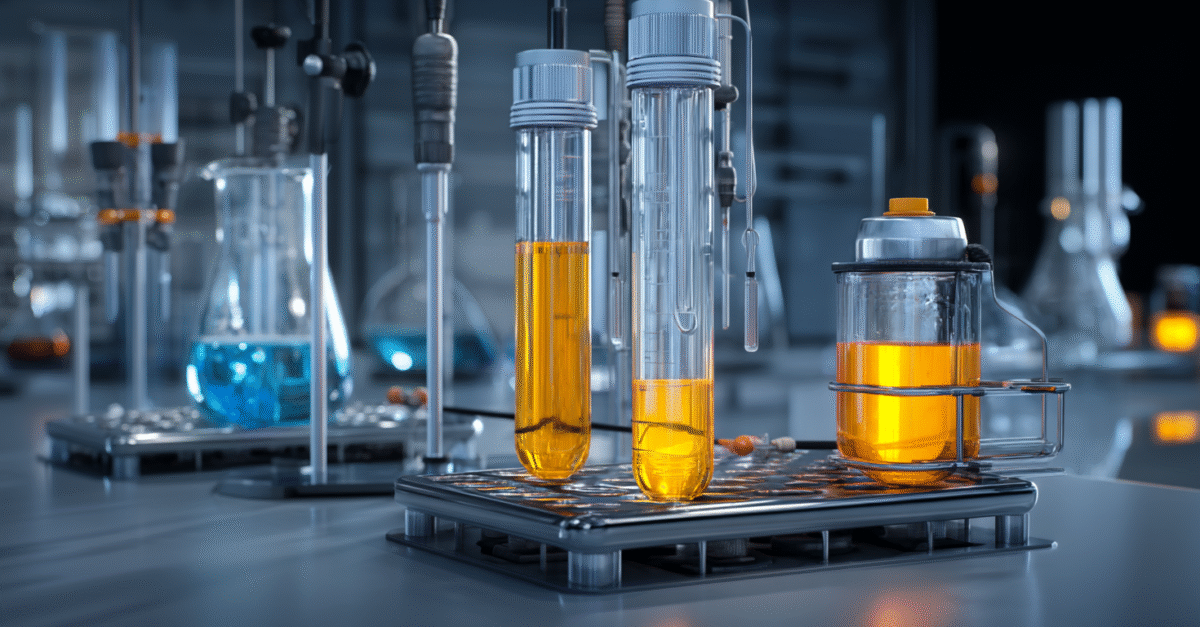

Researchers at the Swiss Federal Institute of Technology in Zurich (ETH) have developed an electrochemical process that converts environmental toxins such as DDT and lindane into valuable industrial chemicals. This technology can be used to clean up contaminated landfill sites or soil on site.

According to a press release, researchers at the Swiss Federal Institute of Technology in Zurich(ETH) have achieved a breakthrough in the remediation of contaminants such as DDT and lindane. These are persistent organic pollutants, or POPs. These are toxic chemicals that were widely used in the 1940s to 1980s. They degrade very slowly and can now be found in the food chain of humans and animals. The university team led by Bill Morandi, Professor of Synthetic Organic Chemistry, has now developed a novel electrochemical process that completely dehalogenates these environmental toxins and binds them in harmless salt. The remaining organic hydrocarbons can be fed into the circular economy and thus serve as valuable raw materials for the chemical industry.

“We wanted to solve one of the biggest environmental problems of the last century. It is unacceptable to leave the dirt to future generations,” Alberto Garrido-Castro, electrochemistry specialist and former postdoc in the group, is quoted as saying in the press release. The ETH team sees the remediation of such contaminated sites in soil, water and landfills as one of the major unresolved issues in environmental protection. The degradation of these chemicals using electrochemical processes has been investigated for some time. According to the press release, the ETH researchers have now achieved the decisive breakthrough with the use of alternating current in electrolysis. “It splits the halogen atoms into harmless salts such as NaCl (common salt) and produces valuable hydrocarbons at the same time,” explains Morandi. The hydrocarbons are benzene, diphenylethane or cyclododecatriene. Chemicals that are used in the production of plastics, paints or coatings and therefore contribute to a sustainable circular economy.

An important prerequisite for implementation is that the new process can be applied not only to pure substances, but also to mixtures of contaminated soil, earth or sludge. The researchers are considering mobile systems that can be used on site, which would eliminate the need to transport these hazardous substances. A prototype has already been successfully tested.